Size

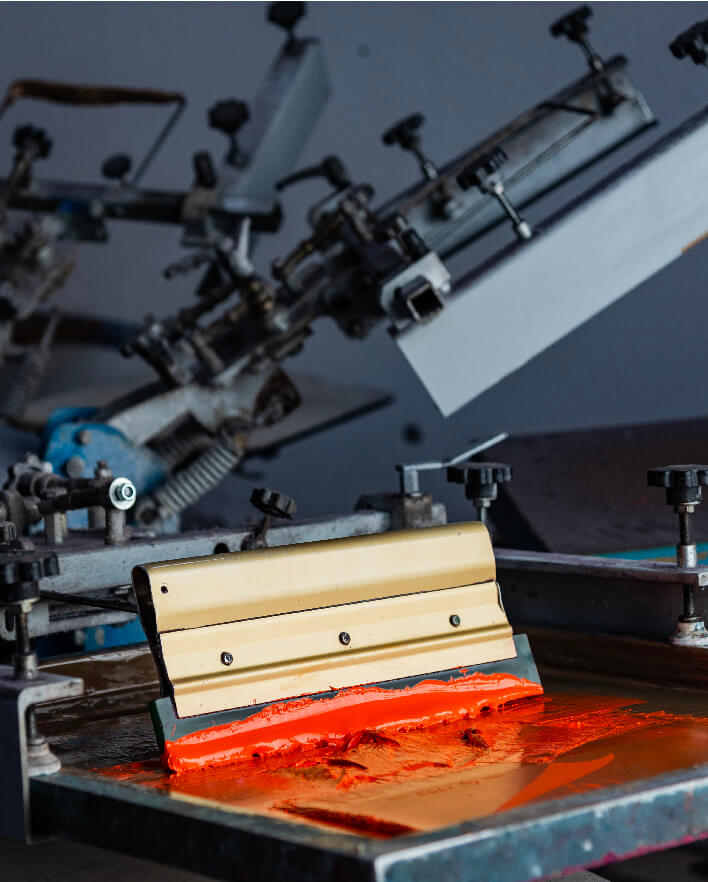

Pallet Tape for Screen Printing

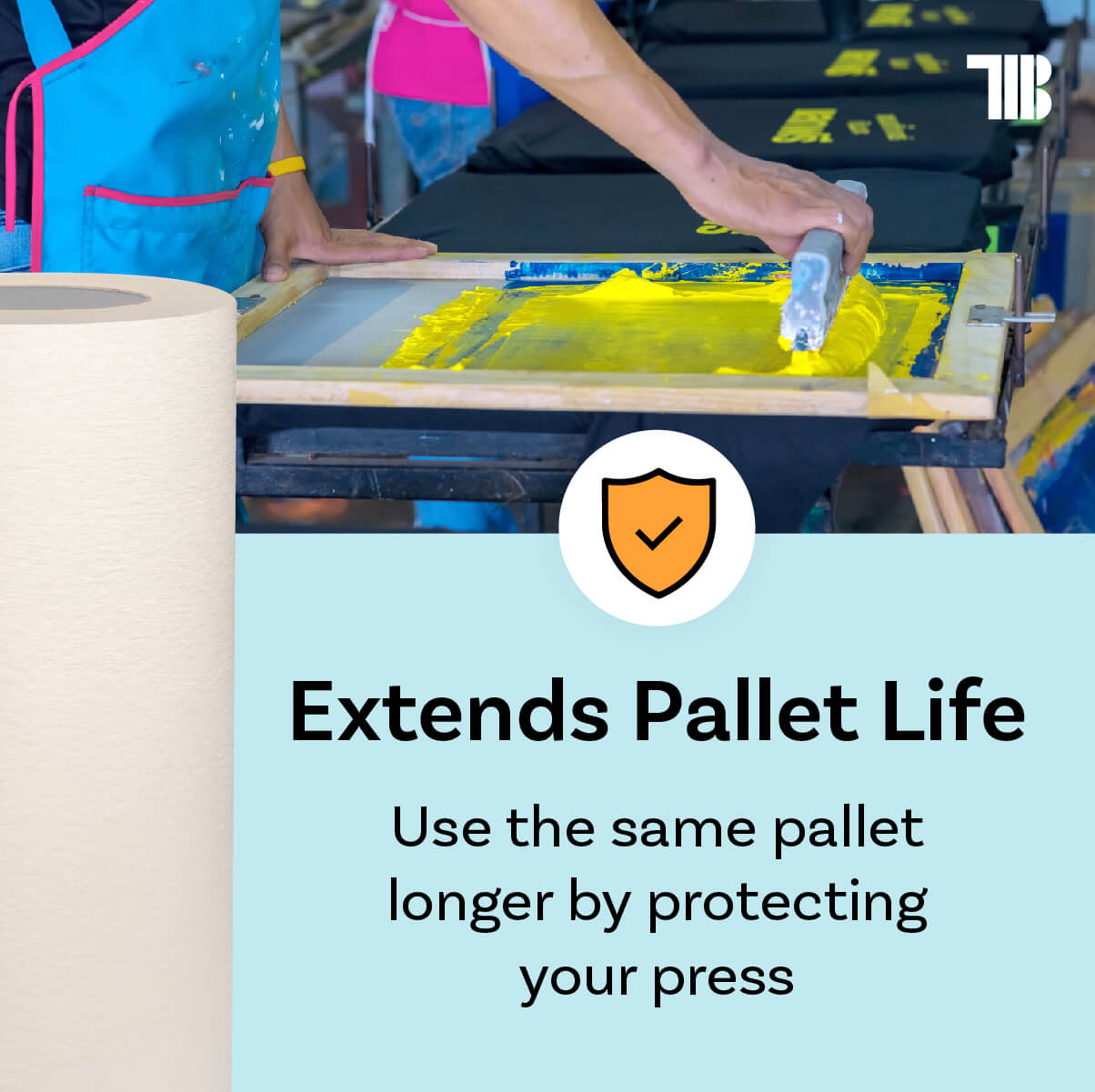

Extends pallet life by protecting your press.

4 mils thick

Ideal for screen printing

Easy to apply and install

Made in America

Free shipping on all orders

Leaves no residue behind

Platen Masking for Screen Printing

- Premium 100 yard long (300 feet) roll of pallet tape that is ideal for screen printing

- 4-mil thickness, natural colored paper

- Protect the print surfaces of your pallet and textile screen print equipment, making your pallets last longer

- Removes cleanly and easily, leaving no residue behind on your printing surface.

- American-made pallet tape you can trust

- Comes in 16 inch, 18 inch, and 24 inch widths

- Free shipping on all orders

Have a question? We're here to help.

Enjoy FREE ground shipping on all orders within the contiguous United States. On select items, expedited shipping is available at an upcharge.

You can return your order within 30 days of purchase for a refund.

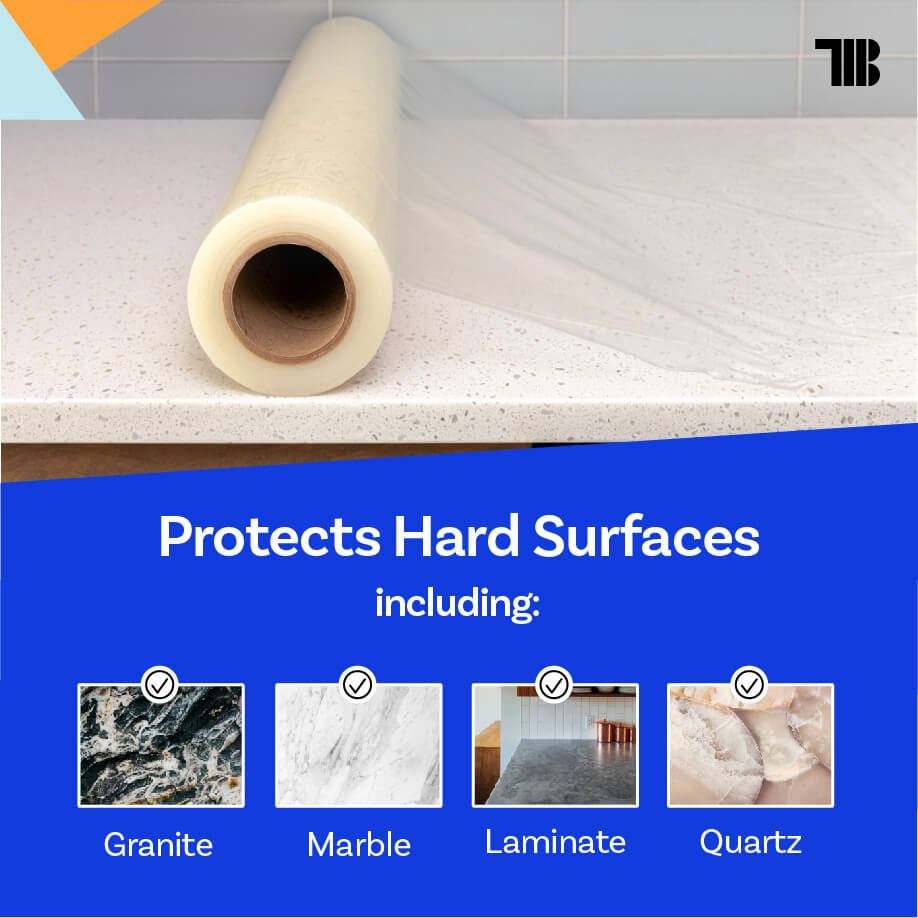

Protect Your Surface with Pallet Tape for Screen Printing

Pallet tape is most commonly used to protect the press during the screen-printing process. At TapeManBlue, we only offer the best products for screen printing, including our platen masking solutions. You’ll find various sizes in our inventory, such as screen printing pallet tape that is 24 inches by 100 yards, 16 inches by 100 yards, and 18 inches by 100 yards.

The key to using platen tape successfully is finding a product that goes on easily, clings durably, and removes quickly without making a mess. That’s exactly what you’ll find in our selection of bulk pallet tape for screen printing — products that are easy to put on, easy to take off and ultimately successful at doing their job. Clean removal is the most desired feature of any pallet tape option, which is why our tape has been designed to deliver clean removal time and again.

How to Use Pallet Tape for Screen Printing

Get Platen Tape Quickly and Affordably

You can find cheap, low-quality products overseas, and you can find better-performing, more-expensive products in the United States. But you won’t find a better blend of affordability and quality when looking for pallet screen printing tape than what you’ll find at TapeManBlue.

We’re able to offer the best prices on pallet tape for platen masking because we run our own operations lean and keep our overhead low. We then pass along those savings to you, the customer. We also offer free shipping on all orders within the continental United States, which brings even more value to your purchase when you choose to work with us for wholesale screen-printing pallet tape.

Without quality products, you can’t do your best work. And without affordability, you won’t be able to sustain your business over the long-term. Choose your platen masking solutions from TapeManBlue, and get the quality and affordability your business needs.

Why Choose Our Pallet Tape?

Free Shipping on All Orders

Free shipping within the contiguous 48 states.

American-Made

Platen masking tape made in the U.S.A. for guaranteed quality.

Quantity Discount Pricing

The more screen printing tape you order, the more you save!

Easy Ordering, Fast Delivery

We ship all orders ASAP so you don't have to wait.

Professional Applications for Pallet Tape for Screen Printing

At-Home Applications for Pallet Tape for Screen Printing

Why Choose Us?

Free Shipping on All Orders

Free Shipping on All Orders

American-Made

Made in the U.S.A. for guaranteed quality.

Wholesale Discount Pricing

The more you order, the more you save!

Easy Ordering, Fast Delivery

We ship all orders within 24 hours.

How Does Pallet Tape Help Screen Printers?

Saves Time

When you place pallet tape on a platen, you'll save yourself a great deal of time with the cleanup stage after your printing job is finished. Instead of having to clean the platen off using a variety of specialty cleaners, the tape will prevent it from ever getting dirty in the first place. You simply have to peel the tape off once you're done using it, saving you lots of time.

Along with the tape's easy removal, its application is stress-free and much faster than other pallet protection products. In order to save time installing the tape, many companies will place several layers of pallet tape onto the platen, so that once you're done with one of the layers of tape, you have another piece waiting for you to use.

Improves Production Volume

Since companies regularly save time after switching to pallet tape, production tends to increase as a result. If you don't currently use pallet tape, consider how much time you or your employees spend cleaning up your pallets. Even if the cleanup process only takes a few minutes, that time is going to add up quickly, with your productivity faltering as a result.

Instead of spending your time producing products for a client, you're stuck trying to get the pallet clean enough and ready to be used again. By making pallet tape a regular part of your company's printing efforts, you'll be setting your company up for increased production and more income as a result.

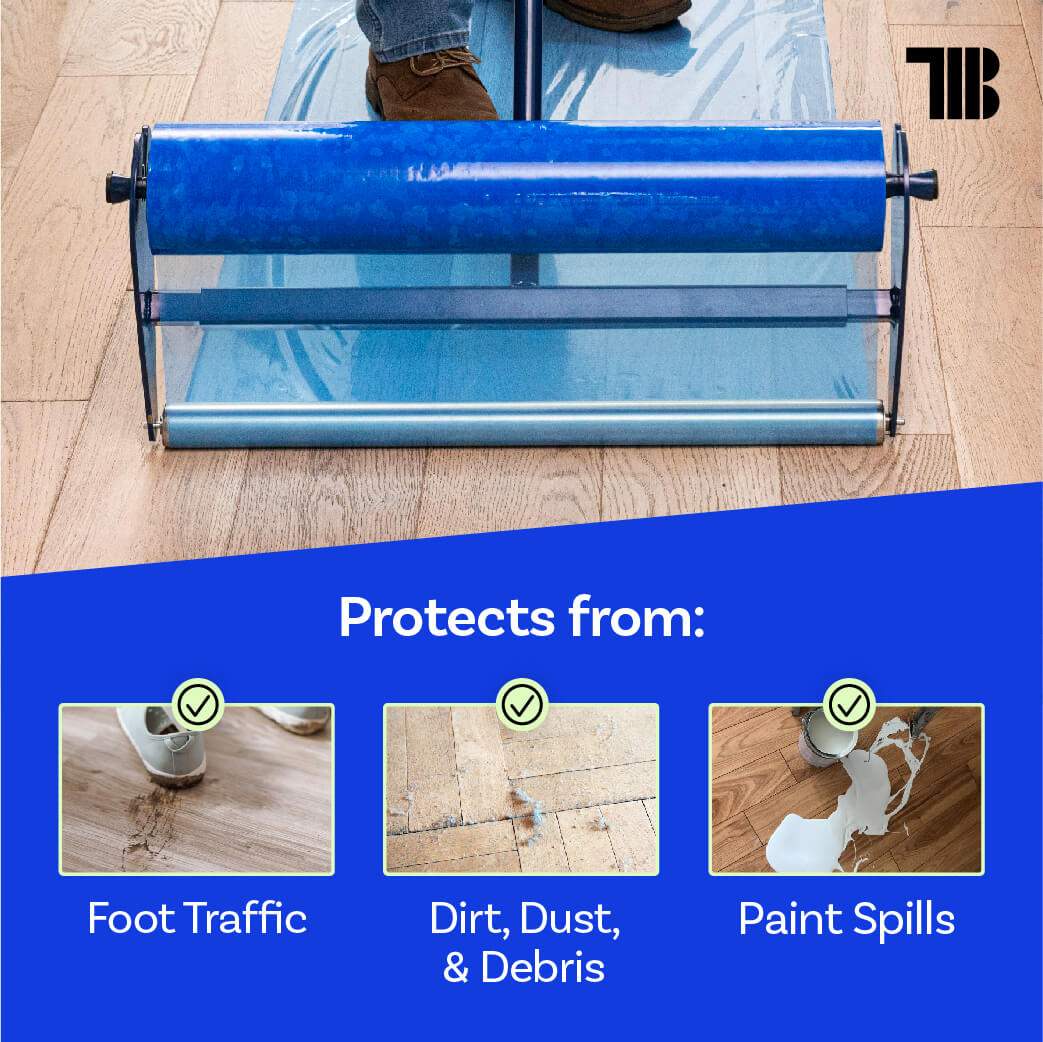

Protects Screen Printing Equipment and Extends the Lifespan of Pallets

Along with the benefits that pallet tape brings to productivity, users can also extend their pallets' lifespans for quite some time. The more you use your platens without any protective covering it, the more you raise the chances of it becoming unusable. Some cleaning supplies can be corrosive to the platen. Over time these corrosive chemicals can wear on the platen, forcing you to purchase a replacement one.

Additionally, if staff begin to neglect cleaning the pallet promptly after use, leftover debris from the previous printing job can end up harming the pallet, forcing you to spend money on a repair or replacement. By consistently using pallet tape to protect your platens, you'll get a longer lifespan out of pallets, saving you money in the long run.

Assists With Cleanup After Printing

Employees who have to clean up after printing jobs are completed know the headache that comes with having to clean the platen, so it's ready to be used again. Cleaning takes up time and, if done sloppily, can result in damage to the platen over time.

Instead of having to use any specialized cleaners, all you have to do to clean up after using pallet tape is peel the tape off of the surface. Those who regularly clean the printer will appreciate the streamlined cleaning process and will have more time for more productive tasks as a result.

Why Use Pallet Tape vs. Alternative Adhesives?

There is some debate about whether other protective adhesive products are better than platen tape. These alternative protective pallet adhesives are often liquid or spray-based. Though these products do have benefits, pallet tape provides superior ease of use and protection.

A common issue with sprays is that once you apply it onto a surface, it also gets into the air. Without even realizing it, you'll be covering various parts of your equipment with the adhesive. Additionally, you have to be careful with sprays to ensure they sufficiently coat the entire surface of the platen, or you may damage the surface during the printing process.

For liquid adhesives, you don't run into the issue of accidentally coating other pieces of the equipment with adhesive, but there is more work required of you. To use a liquid adhesive, you'll often have to squeeze it onto the pallet, spread it over the surface, and, once you're done printing, clean it off manually with water or a specialty cleaner. This whole process can waste time that you could be better spending elsewhere.

Pallet tapes offer the best of both worlds, as the adhesive will never get in the air or make you have to worry that the pallet has been sufficiently coated. Additionally, tape-based pallet adhesives are easier to install and remove, freeing up time for your company to engage in more productive activities.

Your Best Source for Pallet Tape for Platen Masking

When you need platen tape for specific projects or as an ongoing resource, make sure you’re getting the best when you choose TapeManBlue as your provider. At TapeManBlue, we offer nothing but high-quality pallet tape for platen masking. We offer these platen tape screen printing solutions at affordable prices and with bulk discounts. You also enjoy everyday free shipping within the lower 48. Our approach to offering bulk pallet tape for screen printing helps businesses large and small deliver outstanding results while boosting their bottom lines.