Vapor Barrier Tape - Case of 12 Rolls

Heavy-duty, waterproof polyethylene tape.High-tack adhesive

9 mils thick

UV-resistant

Made in America

Free shipping on all orders

Waterproof

- White polyethylene tape for sealing vapor barriers

- 4 inch x 180 foot (60 yards) rolls

- 9 mils thick

- High-tack adhesive for durable protection

- Made in America for quality you can trust

- Free shipping on all orders

Enjoy FREE ground shipping on all orders within the contiguous United States. On select items, expedited shipping is available at an upcharge.

You can return your order within 30 days of purchase for a refund.

Heavy Duty and Durable Vapor Barrier Tape

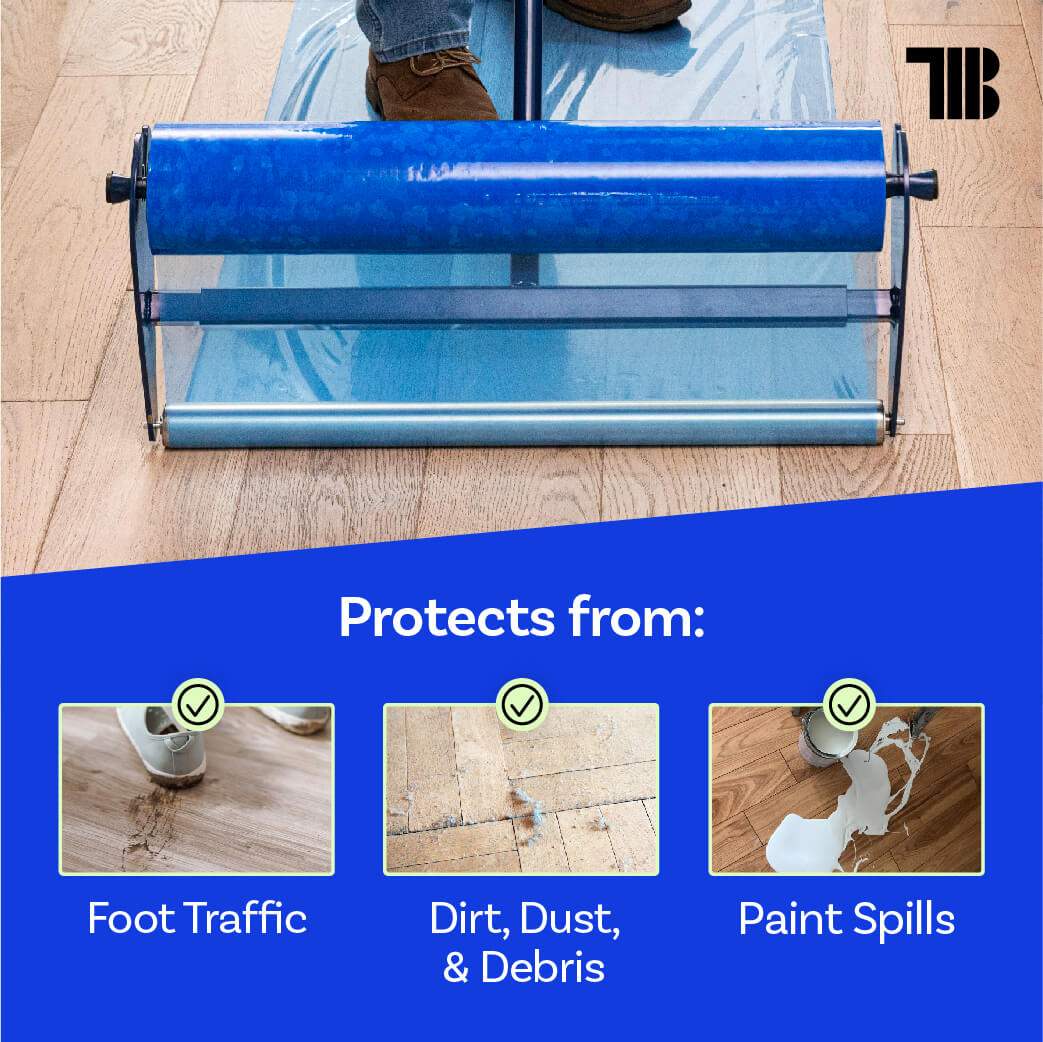

Our premium 4-inch wide vapor barrier tape delivers outstanding performance for critical moisture protection applications. Manufactured with a precise 9.0 mil thick poly film and specialized synthetic rubber adhesive technology, our professional-grade crawl space vapor barrier tape is designed to meet ASTM installation standards. Our moisture barrier tape creates an effective seal with a permeance rating of 0.09 US Perms as verified through ASTM F1249 testing—meeting the requirements for high-performance vapor retarders in construction applications.

Our vapor barrier underlayment tape has proven its effectiveness across diverse environmental conditions in both residential and commercial projects. Construction professionals trust our vapor barrier seam tape for its reliable durability, application versatility, and consistent moisture protection performance in demanding environments. Each roll of our heavy-duty crawlspace tape measures 180 feet long, providing extensive coverage for larger projects while minimizing the number of seams required.

Crawlspace Tape Crafted for Versatility

Our specialized moisture barrier tape excels in multiple critical applications where protection against vapor transmission is essential:

- Abatement: Creates effective seals for containment projects where controlling vapor transmission is critical

- Stucco Painting: Our vapor tape provides surface protection during stucco application with strong adhesion properties

- Building Sealing: Advanced synthetic adhesive creates reliable bonds to polyethylene films while maintaining flexibility across its temperature range

- Marine Preservation:

This tape for plastic sheeting performs effectively in high-humidity environments requiring moisture control

Our white insulation tape utilizes synthetic rubber adhesive technology developed specifically for moisture barrier systems. Our vapor barrier tape provides strong adhesion across diverse substrates including poly-liners, concrete, and other construction materials, creating reliable seals that help control moisture migration across critical barrier transitions. The underlayment seam tape creates continuous protection at vulnerable joint areas where moisture intrusion often occurs.

Why Choose Our Vapor Barrier Tape?

Free Shipping on All Orders

Free shipping within the contiguous 48 states.

American-Made

Made in the U.S.A. for guaranteed quality.

Quantity Discount Pricing

The more crawl space tape you order, the more you save!

Easy Ordering, Fast Delivery

We ship all orders ASAP so you don't have to wait.

Professional Applications for Vapor Barrier Tape - Case of 12 Rolls

At-Home Applications for Vapor Barrier Tape - Case of 12 Rolls

Why Choose Us?

Free Shipping on All Orders

Free Shipping on All Orders

American-Made

Made in the U.S.A. for guaranteed quality.

Wholesale Discount Pricing

The more you order, the more you save!

Easy Ordering, Fast Delivery

We ship all orders within 24 hours.

Polyethylene Tape with Effortless Application & Professional Results

The easy application of the seam tape saves time and reduces the risk of mistakes. Whether you're protecting surfaces during painting, installing insulation, or repairing a boat hull, the versatility of our vapor barrier tape effortlessly ensures a professional outcome. Count on our crawlspace vapor barrier tape's durable nature to streamline your work process and consistently deliver exceptional results.

Independent testing confirms our moisture barrier tape maintains functional performance across its specified temperature range. The crawl space tape can be applied in temperatures from 30°F to 160°F (-1°C to 71°C) and performs effectively in operating temperatures ranging from 20°F to 200°F (-7°C to 93°C), making it suitable for most climate conditions and seasonal variations. This versatile polyethylene tape maintains its protective properties throughout typical building lifecycles.

UV-Resistant and Weatherproof Moisture Barrier Tape

Our premium vinyl seam tape incorporates UV stabilizers that help protect against ultraviolet degradation, extending the tape's functional lifespan in construction applications that may experience prolonged exposure before final enclosure. The white insulation tape's visibility makes it easy to verify complete coverage during inspection.

The 9.0 mil thick poly film used in our moisture barrier tape provides good tensile strength with 63% elongation capability. Laboratory testing according to ASTM D-1000 standards verifies the tape's 33 lb/in tensile strength, ensuring effective performance in typical construction environments. Our crawl space vapor barrier tape creates reliable protection in below-grade applications where moisture control is critical.

Moisture testing using ASTM F1249 protocols confirms our vapor barrier underlayment tape maintains a permeance rating of 0.09 US Perms with a water vapor transmission rate (WVTR) of 0.22 g/100 in²/24 hrs. This performance makes our tape for plastic sheeting suitable for vapor retarder applications in crawlspaces, basements, and other installations requiring effective moisture control to help reduce conditions that promote mold, mildew, and structural deterioration.

American-Made Quality: The TapeManBlue Advantage

Our vapor barrier seam tape proudly represents American manufacturing excellence. Produced in USA facilities, each roll of crawlspace tape undergoes stringent quality control that only domestic production can ensure:

Superior American-Made Materials: We source and use only premium US-made components that maintain consistent performance properties with the reliability that foreign alternatives cannot match

Made in USA Quality Assurance: Our vapor tape production adheres to rigorous American manufacturing standards with quality verification processes that exceed imported options

Domestic Production Consistency: You can depend on the same excellent performance with every roll of our US-manufactured polyethylene tape, supported by American jobs and expertise

For best results, store your underlayment tape in controlled conditions between 60-80°F at moderate humidity. These conditions preserve the tape's adhesive properties and ensure reliable performance when you need it most. Our white insulation tape maintains its adhesive properties when stored properly, giving you confidence when it's time to apply.

By choosing our American-made vapor barrier tape, you support domestic manufacturing while receiving a superior product specifically engineered to create sealed systems that meet or exceed US construction standards. The crawl space tape's performance characteristics make it a dependable Made in USA choice for professionals who demand effective moisture control solutions in challenging environments.

Unlike imported alternatives that often fail in demanding conditions, our American-made vapor barrier seam tape delivers consistent performance throughout its service life. Our domestic insulation tape's proven adhesion strength and durability ensure reliable performance you can trust. This American-manufactured tape for plastic sheeting provides long-term performance in critical moisture protection systems where failure is not an option and only the best will do.

FAQ

Our moisture barrier tape features a 9.0 mil thick poly film with synthetic rubber adhesive engineered specifically for creating effective seals on polyethylene barriers. The tape demonstrates strong adhesion properties (134 oz/in to steel, 64 oz/in to backing) and maintains a permeance rating of 0.09 US Perms, making it appropriate for vapor retarder applications in construction projects.

Yes, our synthetic rubber adhesive is formulated to create strong bonds with polyethylene vapor barriers used in standard construction applications. The tape's adhesive system is engineered to maintain effective seals at critical seam junctions. It performs reliably with properly prepared vapor barrier materials used in typical construction installations.

Our moisture barrier tape can be applied in temperatures ranging from 30°F to 160°F (-1°C to 71°C). Once applied, the tape maintains its functional properties in operating temperatures from 20°F to 200°F (-7°C to 93°C), making it suitable for most climate zones and seasonal variations. For optimal results, we recommend application within the specified temperature range and according to proper installation techniques.

For effective installations, we recommend clean, dry surfaces before applying the tape to vapor barrier seams. Apply the tape with firm pressure to activate the adhesive and create a proper bond. The 4-inch width provides good coverage for standard vapor barrier overlaps. For best results, apply the tape according to project specifications and construction best practices for vapor barrier seam sealing.

Yes, taping all vapor barrier seams is absolutely necessary for effective moisture control. Each untaped seam creates a pathway for moisture vapor to bypass the barrier, potentially leading to condensation, mold growth, and structural damage. Construction best practices and building codes require complete sealing of all vapor barrier seams, overlaps, penetrations, and terminations. Our 4-inch wide vapor barrier tape provides optimal coverage for creating properly sealed, code-compliant installations.

No, duct tape is not recommended for vapor barrier applications. Standard duct tapes use rubber-based adhesives that typically break down over time when exposed to moisture and temperature fluctuations. Our specialized vapor barrier tape with synthetic rubber adhesive technology maintains its adhesive properties, providing the long-term performance critical for effective moisture control that duct tape cannot deliver.

Yes, taping vapor barrier seams is essential for creating an effective moisture control system. Untaped seams create pathways for moisture vapor transmission that compromise the entire system's effectiveness. Building codes and industry best practices, including ASTM installation standards, specifically require sealed seams in vapor barrier installations. Our 4-inch wide vapor barrier tape is designed specifically for creating properly sealed barriers.

Failing to tape vapor barrier seams properly can lead to serious consequences including moisture intrusion, mold and mildew growth, structural damage, reduced insulation effectiveness, and poor indoor air quality. Untaped seams create direct pathways for water vapor to bypass the barrier system.

No, standard construction tapes like masking tape, packaging tape, or general-purpose building tapes are not suitable for vapor barrier applications. These tapes lack the specialized adhesive technology, moisture resistance (our tape is rated at 0.09 US Perms), temperature performance (20°F to 200°F operating range), and adhesion strength (134 oz/in to steel) required for long-term vapor barrier sealing. Using improper tape can compromise the entire moisture control system and lead to costly remediation.